Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

What Are You Looking For?

What Are You Looking For?

Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

We provide high-strength forged/cast metal track cores for heavy machinery. OEM services are available, and we accept drawings or samples for customized production.

Item No :

Durable Forged/Cast Metal Cores for Rubber TracksOrder(MOQ) :

100 PcsPayment :

TT, LCProduct Origin :

ChinaColor :

/Shipping Port :

Mainland ChinaLead Time :

30 daysProduct Description

Forged/Cast Metal Cores for Rubber Tracks: Engineered for Extreme Durability

The forged/cast metal cores are critical components in rubber track systems, designed to deliver exceptional strength and longevity under the most demanding conditions. Utilizing advanced forging techniques and premium materials, we ensure each core provides reliable performance for construction, agricultural, and industrial machinery.

Key Features & Benefits:

1. Premium Material Selection

o Forged from high-grade 45# carbon steel and 40Cr alloy steel, offering superior tensile strength and resistance to deformation.

o Casting made from high-strength ductile iron FCD400-500 can be used to produce parts with complex shapes, wide adaptability and

can process common industrial metal materials.

2. Precision Forging Process

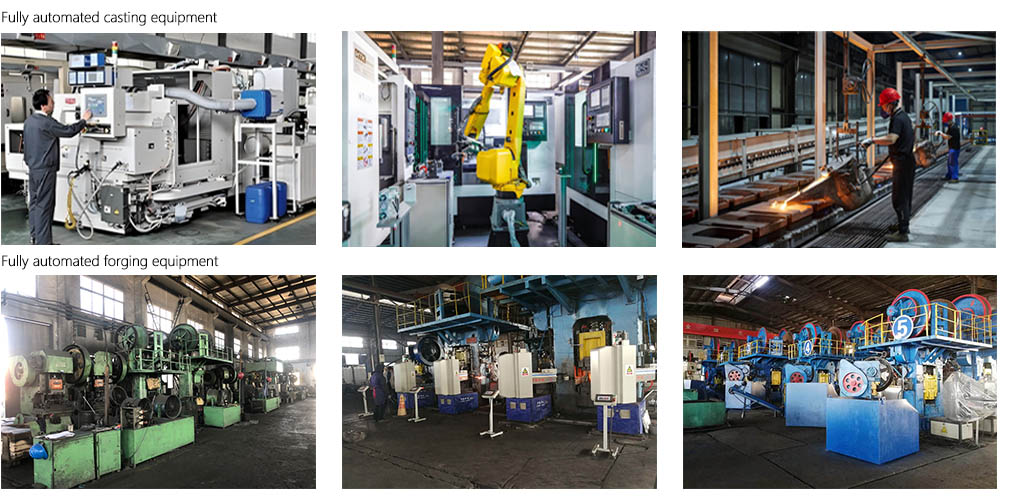

o Advanced forging/casting technology and first-class automated equipment ensure dense internal structure, precise production, and enhanced

impact resistance and fatigue life of the products.

3. Customization Flexibility

o Support custom production based on client drawings or samples, accommodating various sizes and specifications for rubber tracks.

4. Comprehensive Quality Assurance

o Strict control across forging/casting, heat treatment, and machining processes, including dimensional checks and hardness testing.

5. Wide Applicability

o Applied for compact track loaders (CTLs), multi-terrain loaders (MTLs), mini excavators, agricultural tracked equipment, industrial track systems and construction machinery.

Scope of application

o Industrial Track Systems

o Agricultural Equipment Tracks

o Construction Machinery Rubber Tracks

Close cooperation with factories

We maintain deep, long-term partnerships with the factory around 20 years. The factory has strong mechanical and automated production capabilities which ensure stable quality and performance of the forgings/casting and good consistency.

Quality Control

The factory's rigorous quality control process includes material spectroscopy analysis, in-process inspections, and final checks with Magnetic Particle Testing (MPT) to ensure every bucket is free from defects and meets our high standards. The details controll process as below,

1. Incoming raw materials undergo random sampling and analysis using a microscope to ensure the chemical composition meets production requirements.

2. During the production process, QC staff conduct timely sampling to ensure products are defect-free and handle any abnormal quality issues that may arise.

3. The final step involves using a magnetic particle flaw detector on metal parts to detect hidden cracks or defects.

4. All finished metal parts are proportionally sampled and sent to the laboratory for mechanical performance tests, size measurement, and 100% manual surface quality inspection.

Tags :

Leave A Message

Scan to Wechat/Whatsapp: