Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

What Are You Looking For?

What Are You Looking For?

Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

We provide premium automobile engine camshafts through excellent design, high-quality materials,precise construction,stable operation and extremely clean.And OEM services offered, accept drawings or samples for customized production.

Item No :

High-Performance Automobile Engine CamshaftsOrder(MOQ) :

100 PcsPayment :

TT,LCProduct Origin :

ChinaColor :

/Shipping Port :

Mainland ChinaLead Time :

30 daysWe provide the products through years industry experience, full set of advanced machines, complete inspection process which ensure our products got the below features.

(1)Excellent Design: Scientifically designed contours meet engine performance targets.

(2)High-quality materials: Wear-resistant and fatigue-resistant, ensuring a long lifespan.

(3)Precise Construction: Extremely precise manufacturing, perfectly replicating the design.

(4)Stable Operation: Excellent dynamic balancing ensures smooth operation.

(5)Extremely Clean: Meets cleanliness standards, ensuring no impact on engine lifespan.

Scope of application

Automobile Engine

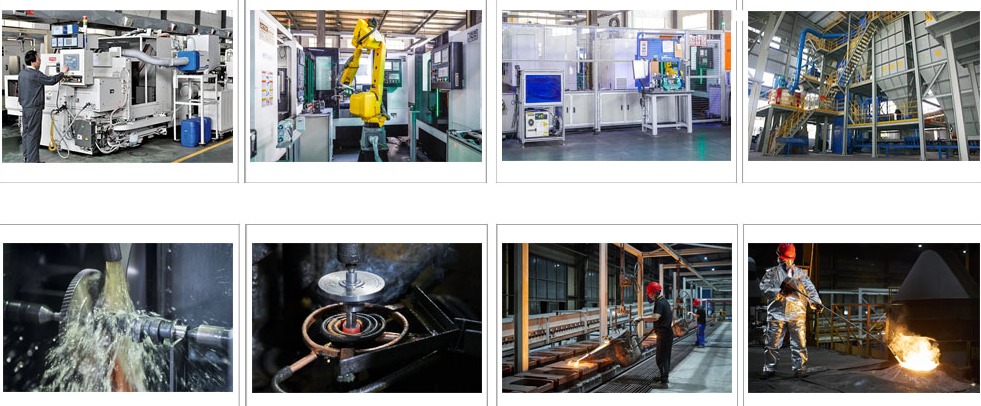

Close cooperation with factories

We maintain deep, long-term partnerships with the factory around 20 years. The factory has strong mechanical and automated production capabilities which ensure stable quality and performance of the products.

Quality control

The factory's rigorous quality control process includes material spectroscopy analysis, in-process inspections, and final checks with Magnetic Particle Testing (MPT) to ensure every bucket is free from defects and meets our high standards. The details controll process as below,

1. Incoming raw materials undergo random sampling and analysis using a microscope to ensure the chemical composition meets production requirements.

2. During the production process, QC staff conduct timely sampling to ensure products are defect-free and handle any abnormal quality issues that may arise.

3. The final step involves using a magnetic particle flaw detector on metal parts to detect hidden cracks or defects.

4. All finished metal parts are proportionally sampled and sent to the laboratory for mechanical performance tests, size measurement, and 100% manual surface quality inspection.

Tags :

Leave A Message

Scan to Wechat/Whatsapp: