Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

What Are You Looking For?

What Are You Looking For?

Tel : +86 -13856582579 Email : Steven.zhao@ypi-trading.com

The Stainless Steel Flat Top Chain, often referred to as a Table Top Chain or Plate Top Chain, is a specialized type of conveying chain designed to create a smooth, continuous, and level surface for transporting goods. Unlike traditional roller chains, its top surface is a series of flat, interlocking plates.

Item No :

/Order(MOQ) :

NegotiablePayment :

TT,LCProduct Origin :

ChinaColor :

NegotiableShipping Port :

Any port in ChinaLead Time :

30 daysProduct Description

Our Stainless Steel Flat-Top Chain is engineered for applications demanding superior hygiene, corrosion resistance, and smooth product handling. Featuring interlocking flat plates that form a continuous, solid conveying surface, it is the ideal choice for the food & beverage, pharmaceutical, packaging, and chemical industries where cleanliness, durability, and reliability are paramount.

Key Features & Benefits

1. Premium Hygiene & Cleanability

2. Exceptional Durability & Strength

3. Smooth & Stable Product Handling

4. High-Temperature & Harsh Environment Resistance

5. Versatile & Customizable Design

Scope of Application

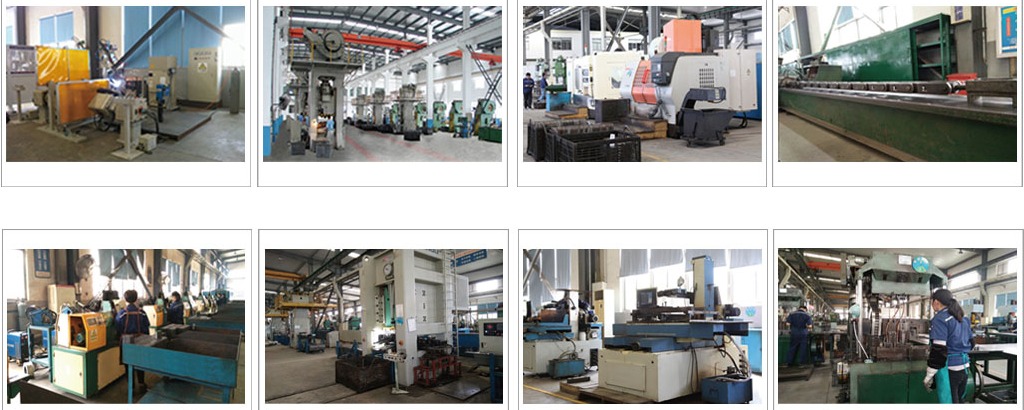

Close cooperation with factories

We maintain deep, long-term partnerships with the factory around 20 years. The factory has strong mechanical and automated production capabilities which ensure stable quality and performance of the products.

Quality control

The factory's rigorous quality control process includes material spectroscopy analysis, in-process inspections, and final checks with Magnetic Particle Testing (MPT) to ensure every bucket is free from defects and meets our high standards. The details controll process as below,

1. Incoming raw materials undergo random sampling and analysis using a microscope to ensure the chemical composition meets production requirements.

2. During the production process, QC staff conduct timely sampling to ensure products are defect-free and handle any abnormal quality issues that may arise.

3. The final step involves using a magnetic particle flaw detector on metal parts to detect hidden cracks or defects.

4. All finished metal parts are proportionally sampled and sent to the laboratory for mechanical performance tests, size measurement, and 100% manual surface quality inspection.

Tags :

Leave A Message

Scan to Wechat/Whatsapp: